Tool engineering & bending tests

Over 35 years of experience flow into tool design, material selection and validated tests - for reliable solutions that are precisely tailored to your requirements. Thanks to comprehensive in-house tests, we guarantee success for the customer, minimise risks and transparently demonstrate possibilities.

Tools are individually designed for your profiles; initial tests often lead to adjustments in order to achieve the highest bending quality. We also check feasibility before investments are made.

Your advantages

- Personal and direct advice

- Assessment of the bendability of your profile

- Modification of cross-sections for optimum bending behaviour

- Engineering, production and testing all from a single source

- Expertise in materials, coatings, lubricating oils and other influencing factors

Mandrel bending device MBD4

- Profile feed unit in 6 m version

- Compressive force approx. 4000 kg

- For bending hollow profiles up to approx. 2.5 x profile width in one pass.

- Servo technology with CNC-controlled mandrel and feed unit (booster).

- Guarantees slip-free bending even of small radii in one pass.

Mandrel bending device MBD20

- Version: 6 m long.

- Pressing force peak 200 kN. Including mandrel retract and mandrel lubrication.

- With this CNC controlled device you can bend hollow profiles in one go.

- Guarantees zero-slip bending of even small radii in a single pass

Demonstration of HELIX Servo + MBD200

Supporting roller controlled

(Z-axis) for 3D bending (right and/or left)

The controlled supporting roller additionally makes it possible to bend with a gradient. With the associated software, it is simple to programme and bend 3D elements.

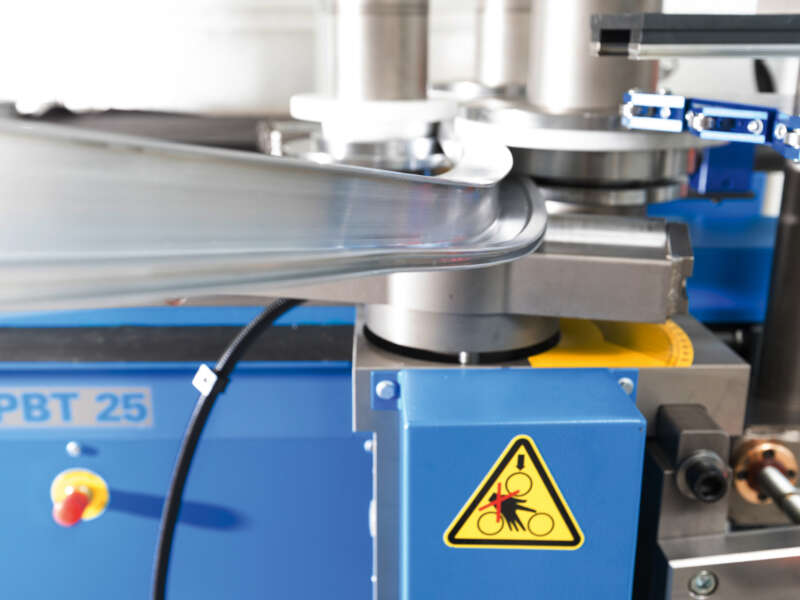

3D bending/turning device

Manual or CNC-controlled, for model PBT25

Allows bending into the third dimension and additional turning of the profiles in two directions.