- Home

- Products

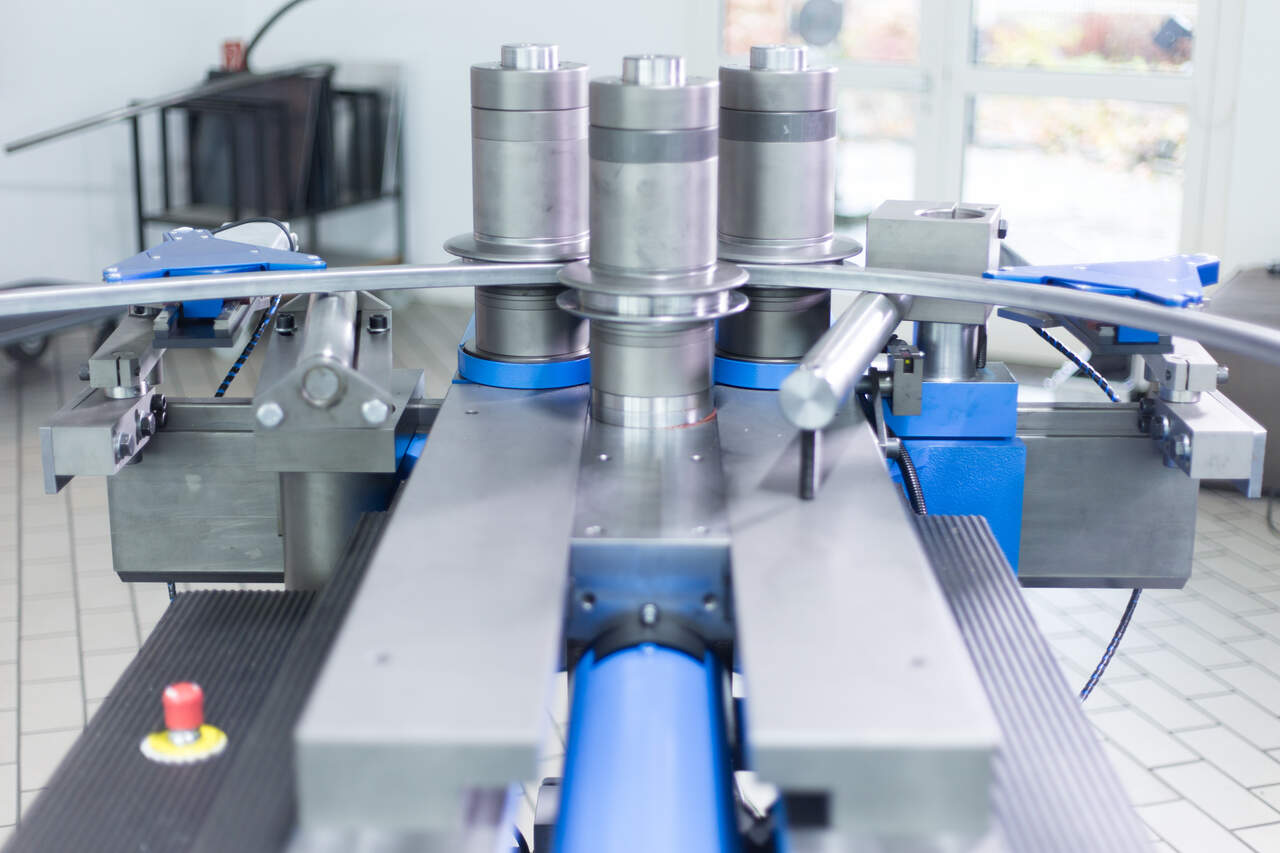

- Profile bending machines

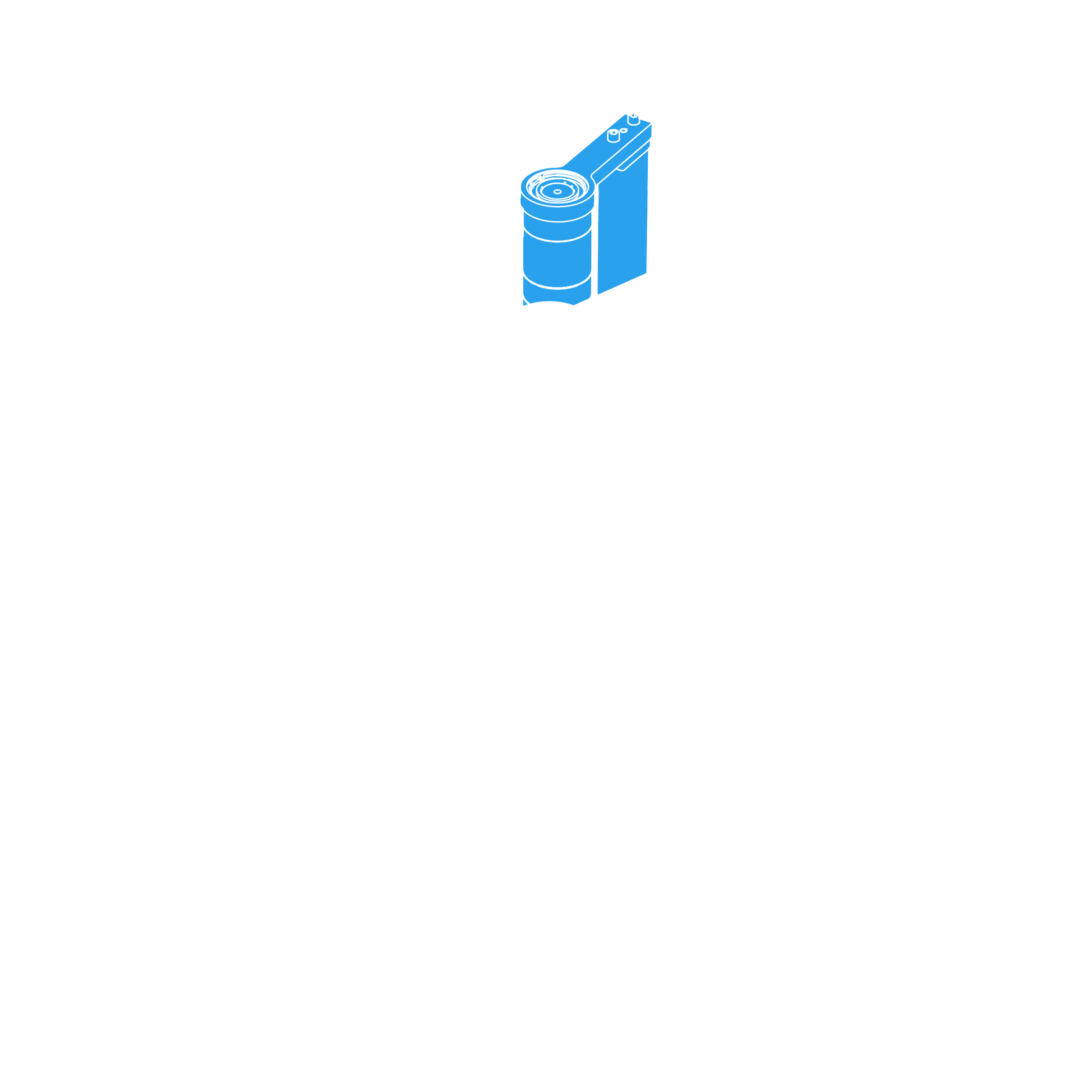

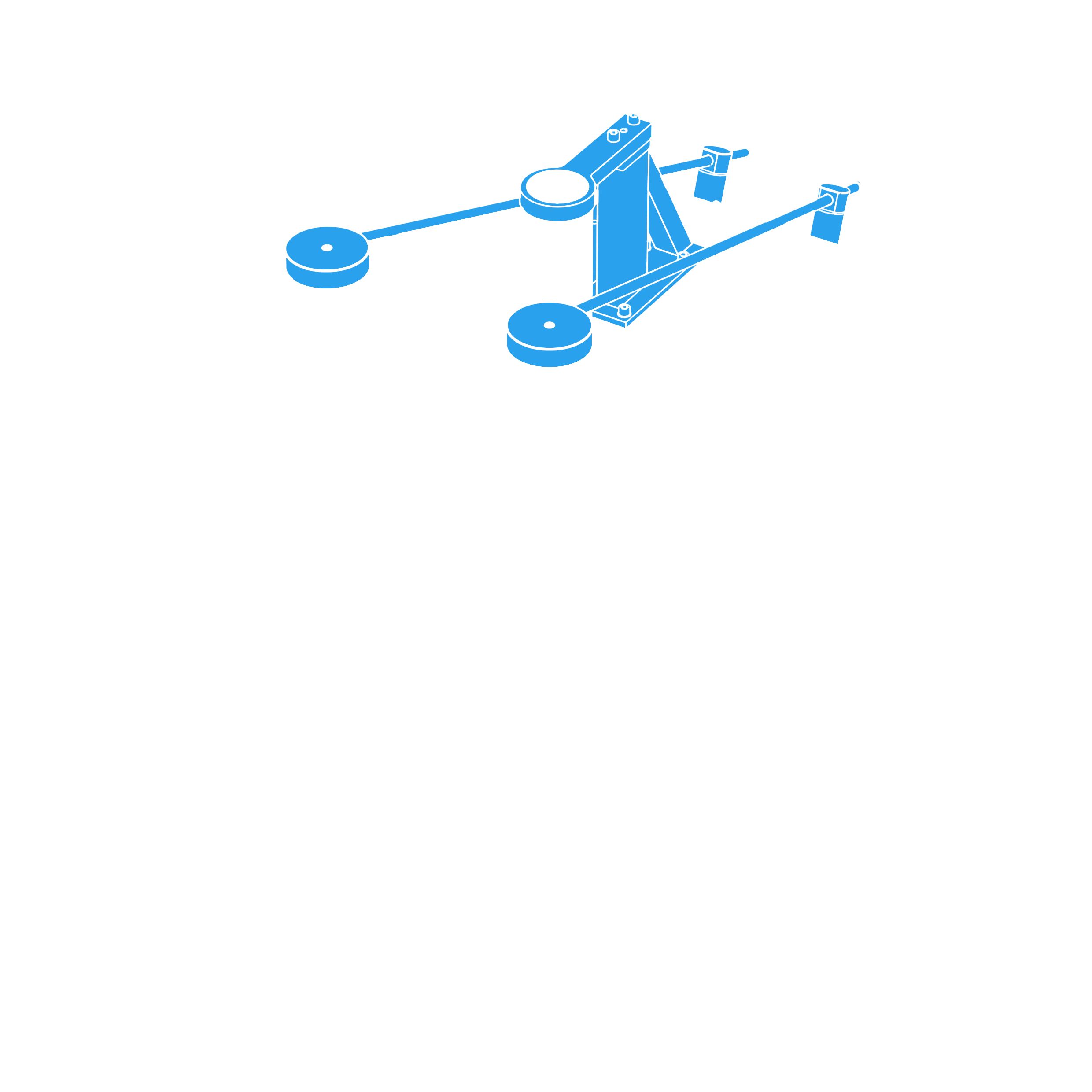

- PBT25®

PBT25® is of a design based on experience, with maximum quality and economy. Due its modular build type it can re-tooled quickly for new work processes. The comparatively high drive rollers allow the bending of profiles up to a height of 300 mm as standard and in maximum quality.

Features

- Continuously adjustable front roller distance: minimal 200 mm – this provides for smallest radii with perfect transitions!

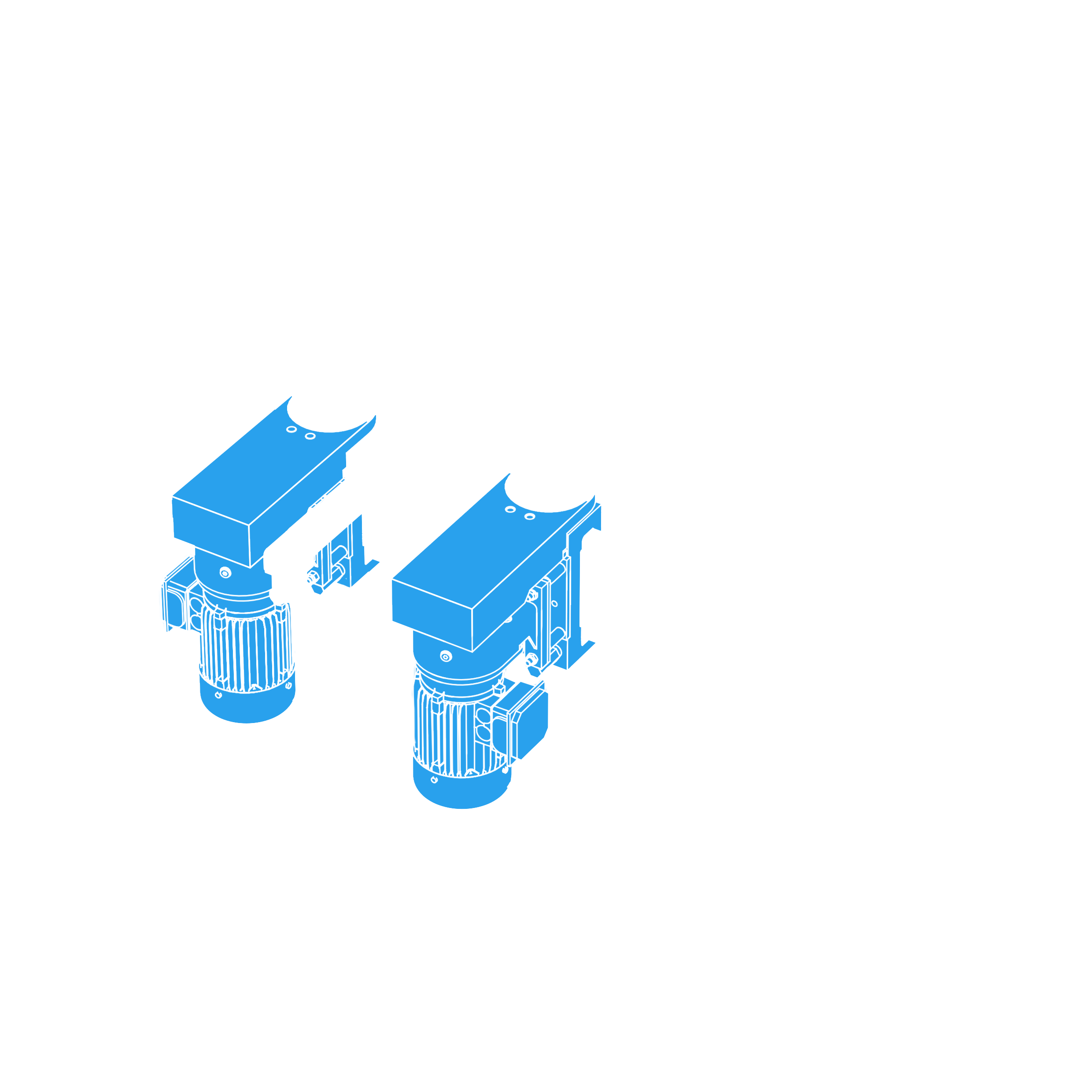

- All 3 rollers driven by powerful, clean and low noise electric motors up to 22 rpm

- Minimum oil volume 18 litres

- Roller support / steady rest for all 3 shafts as series standard without any additional charge

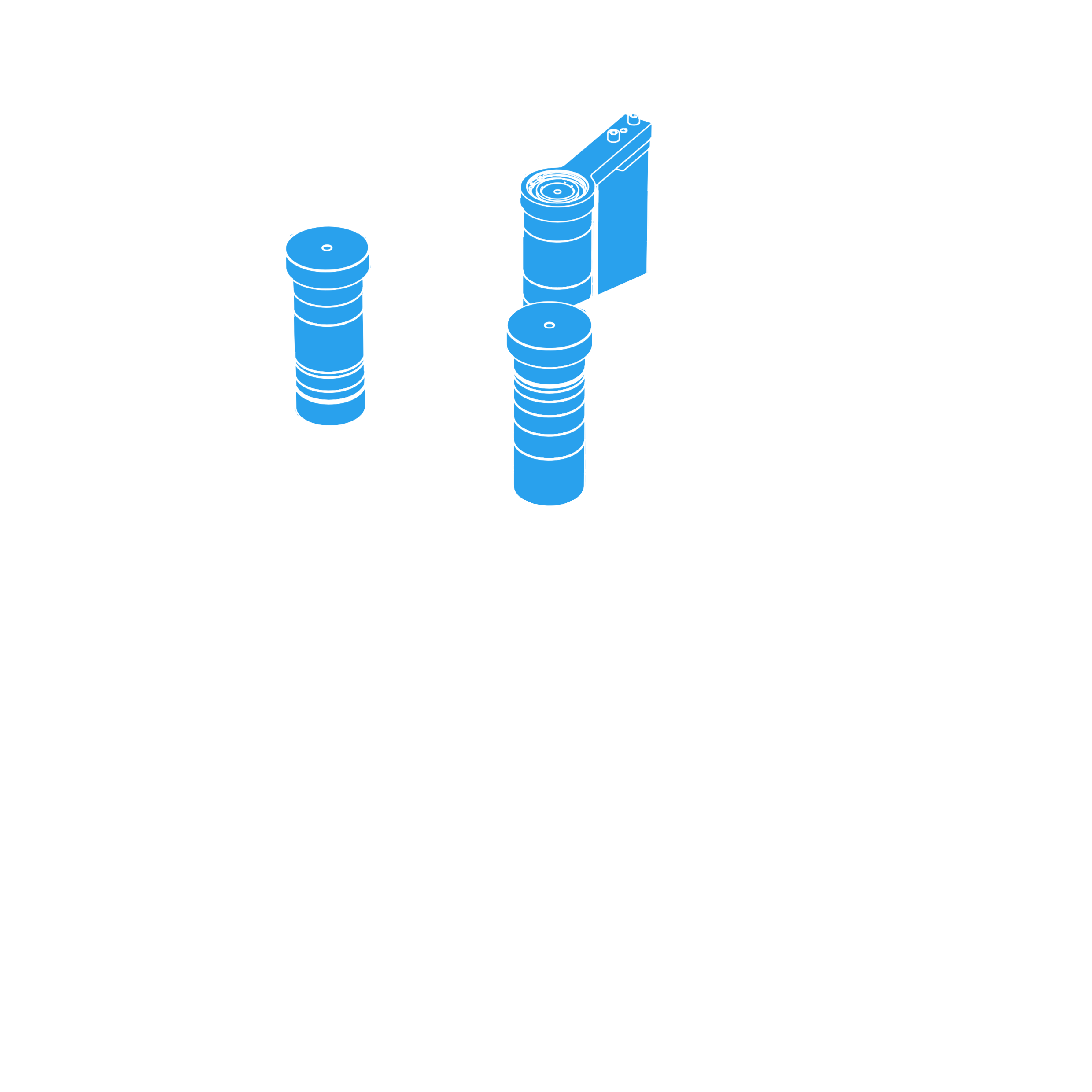

- 300 mm high rollers

- Reduced risk of accidents as bending direction away from operator

- Ergonomic working conditions

- Movable with drawbar

- Working on both sides possible: at the front: rolling; at the rear: chamfering

- High-performance control systems

- Consultation, training and commissioning from experts

- Excellent price/performance ratio

- Swiss quality

- Lower maintenance costs

Control systems

- Manuel / Tablet Teach-In / Tablet350 / PC400

Application areas

Due to their versatility the PBT25 has a wide range of application areas. The machine provides valuable services in innumerable sectors of industry (automotive engineering, conveyor technology, metal construction, metalworking, steel construction, space technology, etc.).

FAQ (frequently asked questions)

The PBT25® is a proven modular profile bending machine, engineered for maximum quality, flexibility, and cost‑efficiency.

It is designed for quick tool changeovers and for bending profiles up to approximately 300 mm in height.

The PBT25® provides several advanced technical features:

Continuously adjustable front roll distance starting at 200 mm for extremely tight radii with smooth transitions

Three powerful, clean and quiet electric motors with speeds up to 22 rpm

Low oil volume of just 17–18 liters – environmentally friendly and low‑maintenance

Standard roller support (steady rest) on all three shafts

Ergonomically optimized design, reduced risk of injury, and two‑sided operation

Mobile design with tow bar

Excellent price–performance ratio and genuine Swiss manufacturing quality

The PBT25® supports four modern control options:

Manual Control – ideal for simple bending tasks

Tablet Teach‑In – perfect for easy, repetitive jobs

Tablet350 – powerful option for recurring series production

PC400 Control System – high‑end solution for precision and automation workflows

All control systems are based on Windows 10, offering graphical program visualization and fast, intuitive operation.

The PBT25® is used successfully across various industries, including:

Workshops, locksmithing and craft industries

Architectural, façade and special profile applications

This makes it one of the most versatile profile bending machines in its class.

The machine weighs 1,150 kilograms, providing excellent rigidity, stability, and precise bending performance.

The PBT25® can bend profiles up to 300 mm in height.

Thanks to its adjustable roll spacing, it can achieve very tight bending radii without deforming the profile cross‑section.

Due to its modular design, the machine can be reconfigured extremely quickly for new tools and bending applications — ideal for workshops with frequent profile changes or small to medium batch sizes.

Yes. The machine is equipped with a tow bar, making it easy to move and position within the workshop or production area.

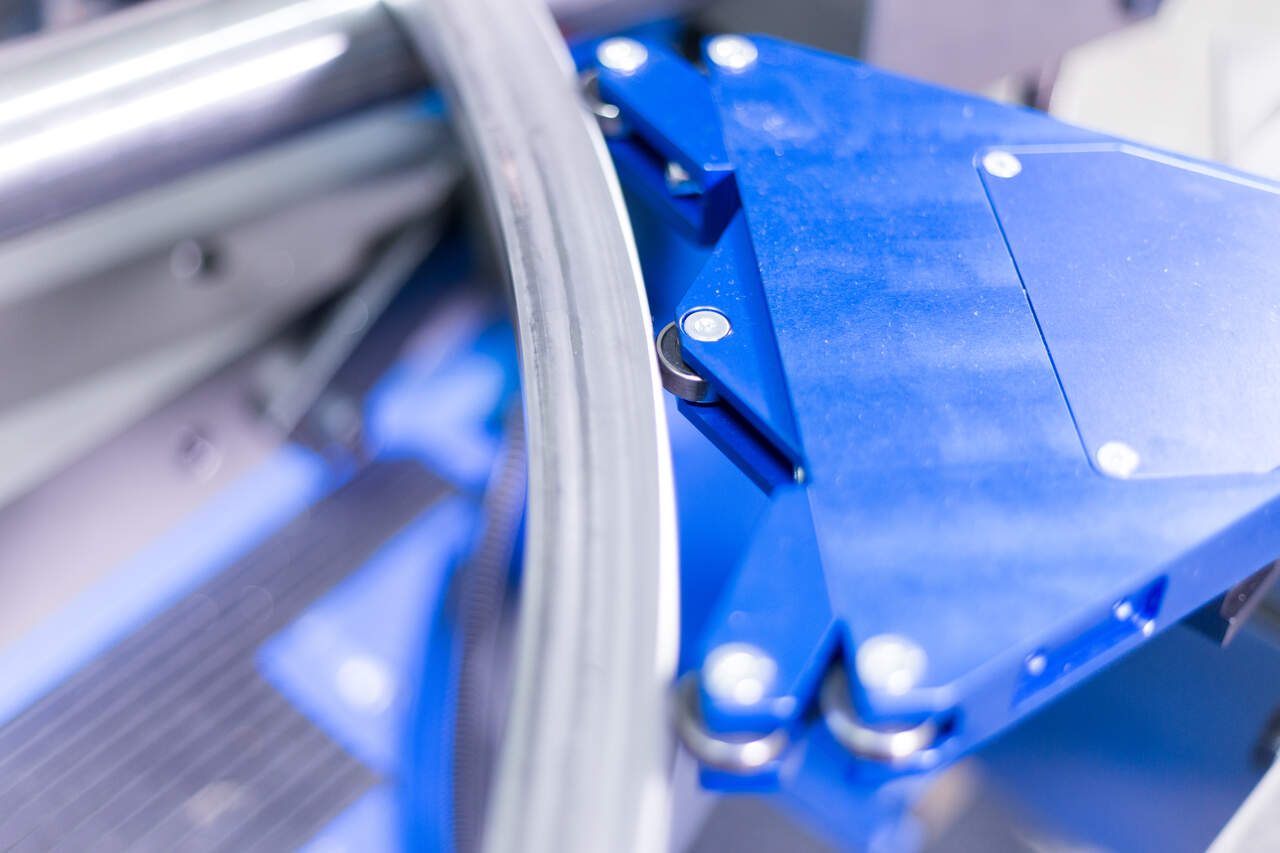

The PBT25® can operate with both standard tools and custom‑engineered tooling solutions. By default, the machine is compatible with tools featuring an inner diameter of 105 mm.

If you require tools with other dimensions, PBT can manufacture special shafts and custom tool interfaces to match your specific profile and application.

Simply get in touch with us — we will review your requirements and provide the optimal tooling solution.

Yes. Its precise roller support, rigid frame construction and customized tooling solutions make it ideal for bending thin‑walled aluminium and decorative profiles without deformation.

Yes. The machine features open interfaces and can be integrated into fully or partially automated production environments, including:

Robotic loading and unloading

Automatic feeding systems

Inline measuring technology

ERP/MES connectivity

Custom automation solutions

This makes the PBT25® future‑proof and Industry 4.0‑ready.

Yes. It is fully compatible with manual and CNC‑controlled mandrel feed systems.

This enables extremely tight radii (down to 2.5 × profile width) with excellent surface quality and minimal deformation.

Fast tool changeovers

Flexible expandability

Easy maintenance

Maximum adaptability

Long‑lasting, robust construction

Seamless integration into production lines

The PBT25® is designed for minimal maintenance effort. Its robust construction, high‑quality components and easy accessibility ensure maximum uptime and efficient servicing.