- Home

- Products

- Accessories & Options

- Radius measuring

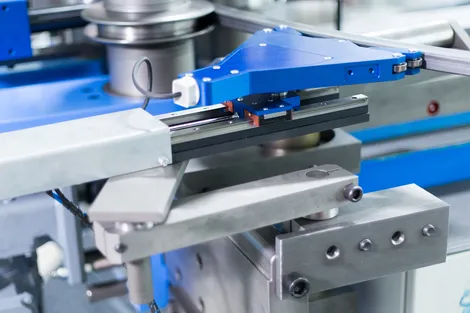

Automatic radius measurement system

Using the automatic radius measurement system, even complex forms with demanding materials can be manufactured without many years of know-how. For many radii it is thus possible to achieve all nominal values without rejects and costly and time-consuming test runs. In most cases even changed material properties can be handled without any problems.

- Fully automatic radius measurement based on our PC400 control systems

- The pneumatic gauge heads can be positioned variably to the right and left of the bending rollers

- Measurement of one or more different radii in the same profile is possible

- Continuous and cyclical measurement of the actual manufactured radius possible

- After measurement of the actual manufactured radius, automatic correction takes place until nominal radius is reached

Your benefits

- Saves time – no monitoring of the bending process by machine operator required

- Saves resources – employees can focus on other tasks during the bending process

- Saves costs – batch-related deviations are a thing of the past

Manual radius measuring device 2.0

Precise determination of the radius is an essential requirement for high-quality bent workpieces and precisely fitting profiles. For this demanding task, we offer you two manual measuring systems that are characterised by simple operation and high precision – customised to your specific requirements.

The delivery includes the measuring device, a battery, three different cord sizes, and a protective case for secure storage and transport.

Wireless measurement – data transmission in real time

In addition to the conventional manual measurement, a modern wireless version is also available. With this option, the radius is determined manually, while the measurement results are transmitted wirelessly and directly to the PC400 control system (required for operation). This significantly reduces the effort needed for manual data entry and minimises sources of error. Corrections and adjustments can be made directly and conveniently via the intuitive touch display of the control system.

Different chord length (both options)

Scale 100 mm

Scale 300 mm

Scale 500 mm