- Home

- Products

- Accessories & Options

- 3D bending

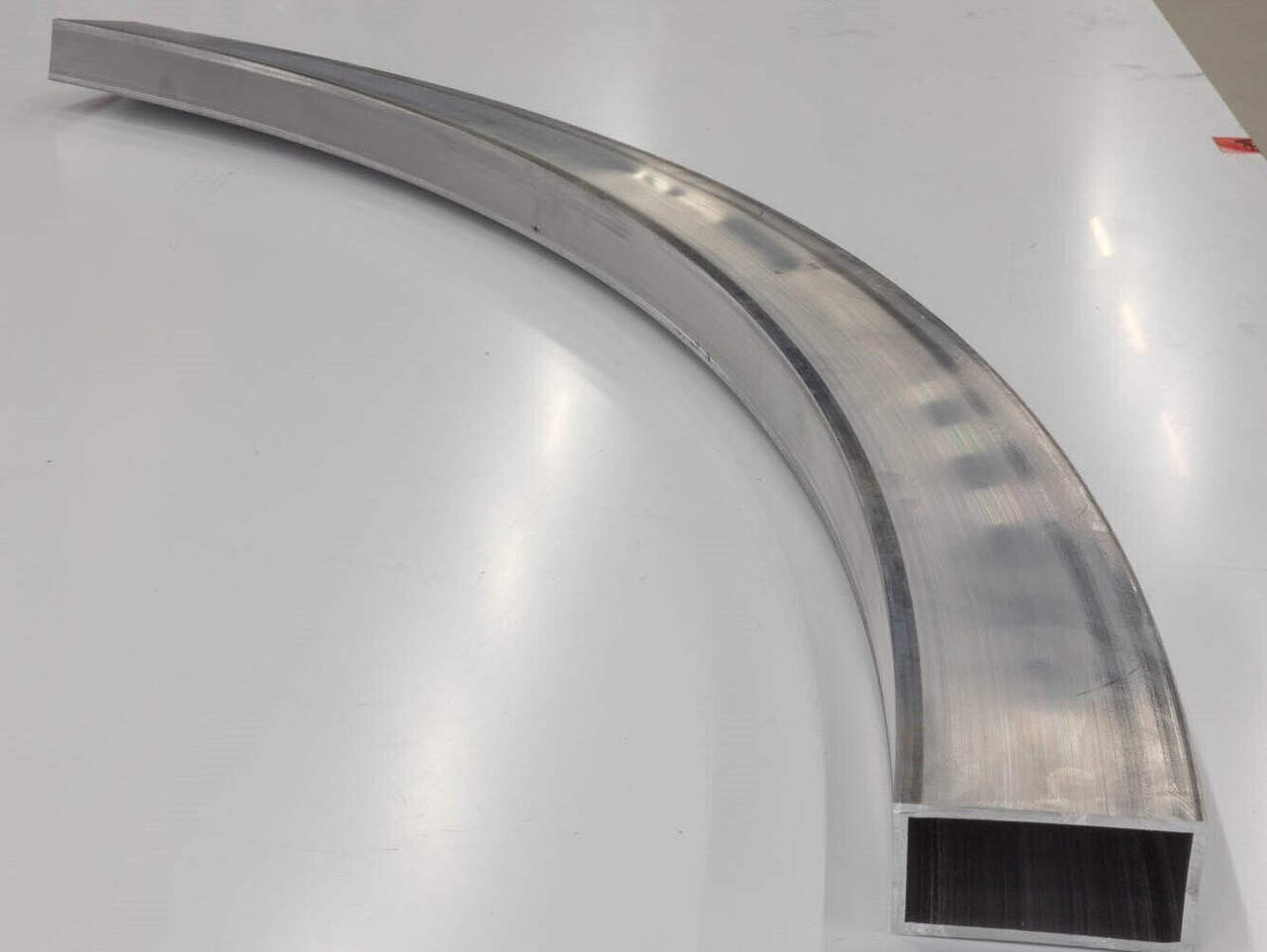

3D bending of a custom profile

As an innovation leader in three-roll bending, we are continuously developing our products and solutions. The requirements for profile geometries and bending solutions are constantly increasing, with the trend increasingly moving towards three-dimensional bending processes. To meet market requirements, we adapt and optimise our products on an ongoing basis.

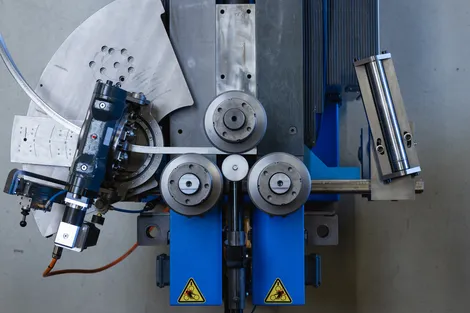

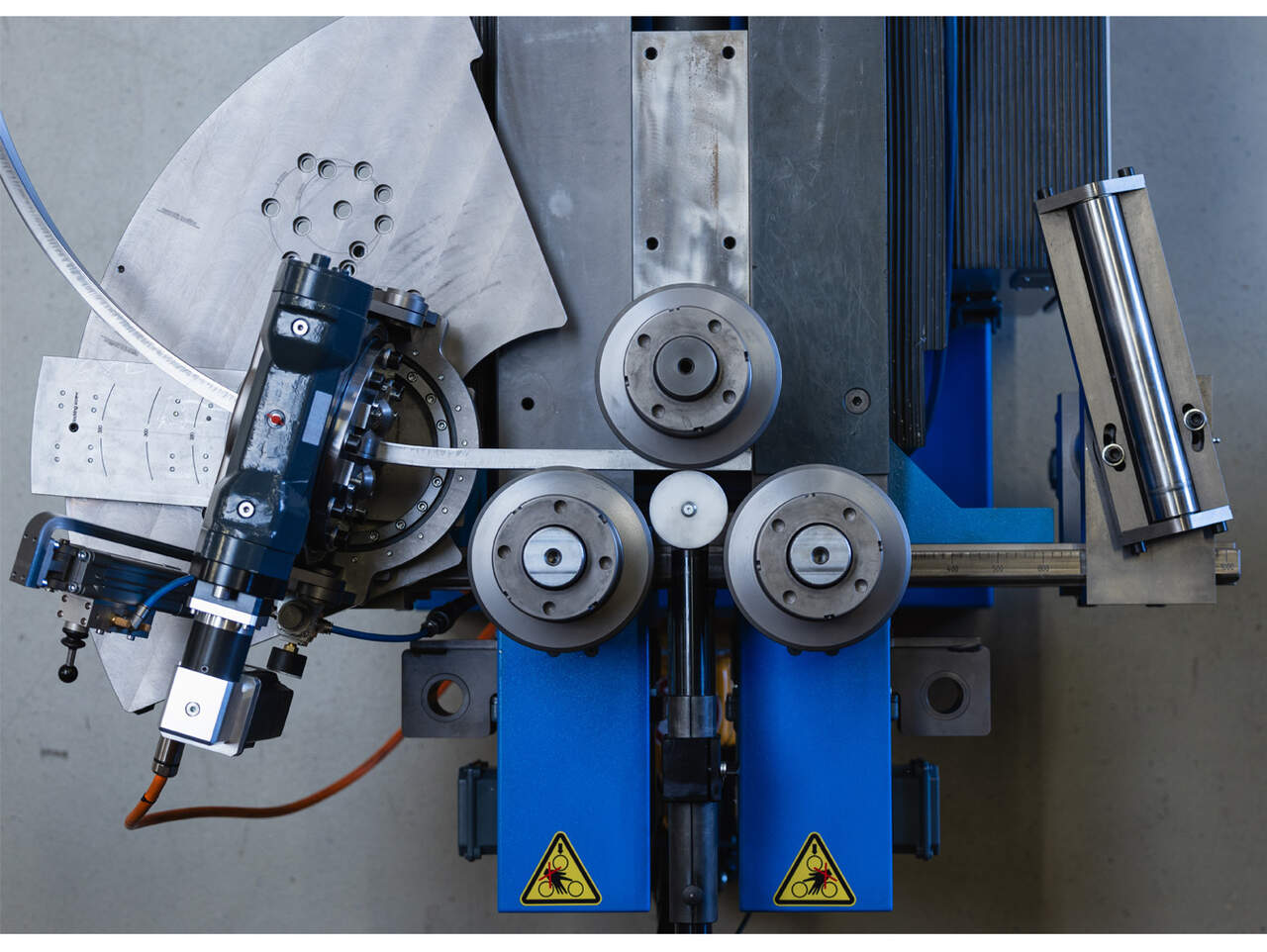

TBD4

Enables precise bending and twisting of standard and special profiles in the third dimension.

Application Range

Bending and twisting of standard and special profiles. Suitable for standard profiles up to 50 × 50 mm and special profiles up to 70 × 70 mm (depending on tensile strength and bending radii). Feasibility depends on material strength and required bending radii and should always be evaluated individually.

Compatible Machines

Can be used with the PBT15 Pro PC400 and PBT25 PC400 bending machines, each equipped with 2T or 4T Z-axes.

System Requirements

Compressed air, PC400 software, and CNC-controlled Z-axis (optional for the PBT25).

Features

High flexibility for customized bending tasks. The TBD4 is compatible with various machine models and can be mounted on both the left and right Z-axis.

Technical Data

Torque: 4,000 Nm

Drive power: 680 W

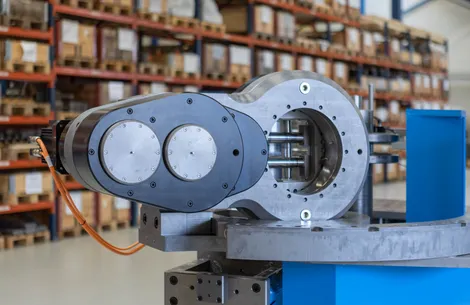

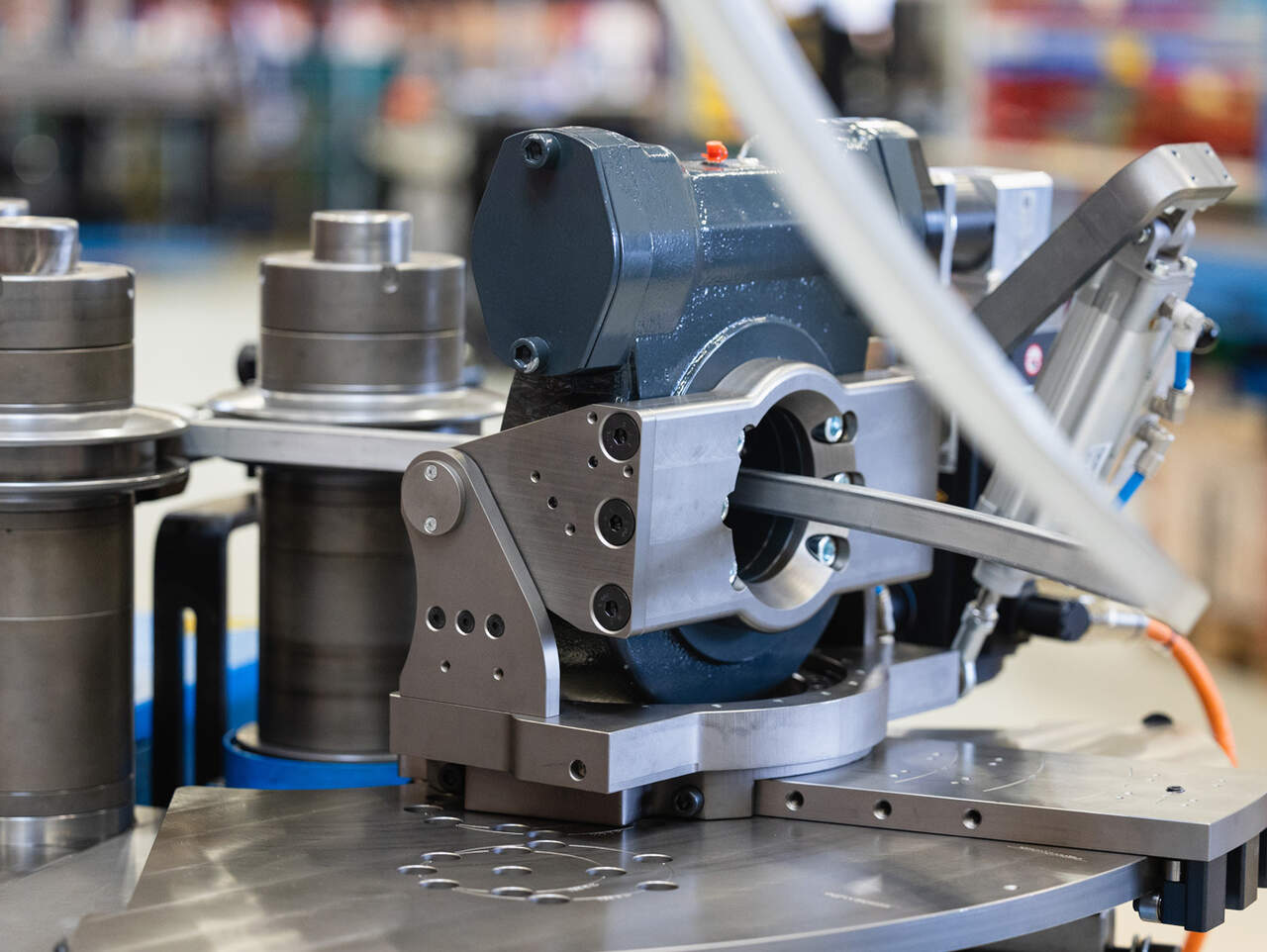

3D bending device TBD20

The 3D bending device enables bending and twisting of various shapes of profiles in the third dimension. It is suitable for profiles up to approximately 170 x 100 mm,and is designed for the HELIX bending machine.

Note: Feasibility depends on material strength and required bending radii and should be evaluated individually.

Required Options: Compressed air, PC400 software, and CNC-controlled Z-axis (included as standard with the HELIX).

Technical Data

-

Torque: 20,000 Nm

-

Drive power: 16 kW

How 3D bending technology expands your possibilities

3D profile bending opens up new dimensions in production. Whether aluminum profiles, steel profiles or other materials – with a 3D bending device, a wide variety of materials can be processed reliably and precisely. The ability to process complex profiles, tubes and other materials in three dimensions means that innovative designs and heavy-duty components can be produced – without additional connecting elements such as weld seams. The result: workpieces with a higher load-bearing capacity, lower material consumption and attractive aesthetics. This not only optimises your production, but also opens up new possibilities in terms of design and functionality.

The 3D bending device is available as an extension for the PBT25® model.

Manual or CNC - which control system suits your requirements?

Depending on your production requirements, we offer different control systems for the 3D bending device. A manual control is particularly suitable for small productions or one-off productions where the bending parameters need to be flexibly adjusted. A CNC control system, on the other hand, offers decisive advantages for mass production or particularly complex bends. In this case, automation guarantees maximum precision and constant reproducibility, which is essential for large quantities and complex components. At the same time, automated control can increase production efficiency.

For which industries is a 3D bending device suitable?

The use of a 3D bending device is particularly recommended for applications where complicated three-dimensional forming is required:

Architecture: In modern construction, curved façades or curved beams are no longer a rarity. The 3D profile bending process can also be used in interior design to bend metal profiles and the like into a wide variety of shapes, such as those used in curved stair-rails for spiral staircases.

Aviation and aerospace: In aviation and aerospace, every detail matters, no matter how precise. Fewer weld seams mean fewer weak points, less weight and improved aerodynamics. With a 3D bending device, even complex shapes can be bent precisely from a single piece – for maximum stability and minimum contact surface.

Amusement park infrastructure: The construction of roller coasters and other rides requires precise, complex curves and structural elements that are both functional and visually impressive. 3D bending makes it possible to shape rails and steel frames exactly according to individual design specifications.

Piping and plant construction: Piping systems often have to be installed in very confined spaces. The 3D bending technology enables complex runs and transitions with millimetre precision without additional joints, which increases tightness and reduces the risk of leaks – ideal for the production of cooling circuits or supply lines.

Furniture construction: In furniture production, irregular and organic shapes are often designed which are difficult to realize with conventional bending processes. A 3D bending device enables the production of curved metal frames or intricate designs for chairs, tables and armchairs.

Technical innovation that revolutionizes your production workflows

With a 3D bending device from PBT AG, you can go one step further towards top quality. This innovative extension makes the profile bending process even more efficient, as unique shapes can be produced directly from a workpiece – in just one step. This not only saves time, but also costs and material while optimising component quality. Whether manual or CNC-controlled, the adaptability of this technology adapts precisely to your specific requirements and takes your production to a new level. See for yourself now – the PBT AG team will be happy to answer any questions you may have.