Automatic Radius Measurement (ARM) system

With PBT's automatic radius measurement system (ARM), even complex forms with demanding materials can be manufactured without error, material waste with operators who may not have years of know-how. For many radii it is thus possible to achieve all nominal values without rejects and costly and time- and material-consuming test runs. In most cases even changed material properties can be handled without any problems.

- Fully automatic radius measurement is based on PBT's PC400 control systems

- The pneumatic gauge heads are positioned variably to the right and left of the bending rollers

- Measurement of one or more different radii in the same profile is possible

- Continuous and cyclical measurement of the actual manufactured radius possible

- Springback is measured and corrected based on the outcome of the initial pass

- After measurement of the actual manufactured radius, automatic correction takes place until the specified radius is reached

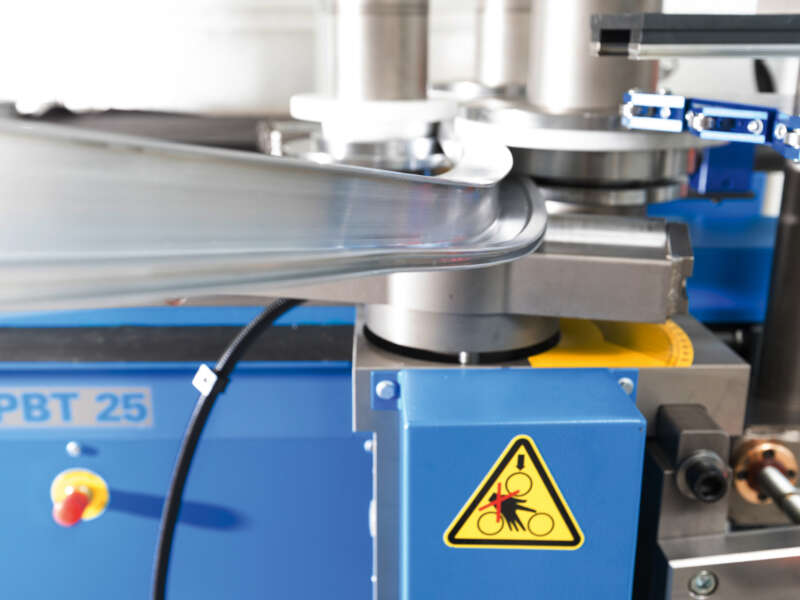

Mandrel bending device - 1500 CNC-controlled

With a PBT mandrel bending device option, operators can achieve clean bends with challenging materials without distortion.

- Profile feed unit in 3m, 4m or 6m versions

- Pressing force approx. 1500 kg

- For bending hollow profiles in a single pass

- Accompanied by a controlled feed unit or booster

- Guarantees zero-slip bending of even small radii in a single pass

- Without fig.: Model 4000 delivers approximately 4000 kg pressing force

Mandrel bending device - MBD200

PBT's MBD mandrel bending device, operators can easily bend hollow profiles.

- Profile feed unit is 6m long

- Pressing force peaks at 200 kN including mandrel retract and mandrel lubrication

- With this CNC controlled device operators can bend hollow profiles in one go, without distortion

- Guarantees zero-slip bending of even small radii in a single pass

Demonstration of HELIX Servo & MBD200

Supporting roller controlled

- (Z-axis) for right and/or left 3D bending

- The controlled supporting roller additionally makes it possible to bend with a gradient. With the associated software, the supporting roller makes it simple to program and bend 3D elements.

►

3D bending/turning device

- Manual or CNC-controlled, for model PBT25

- Allows bending into the third dimension and additional turning of the profiles in two directions