High-precision profile bending machines for the most challenging applications

More Information

Innovative bending technology for more than 30 years

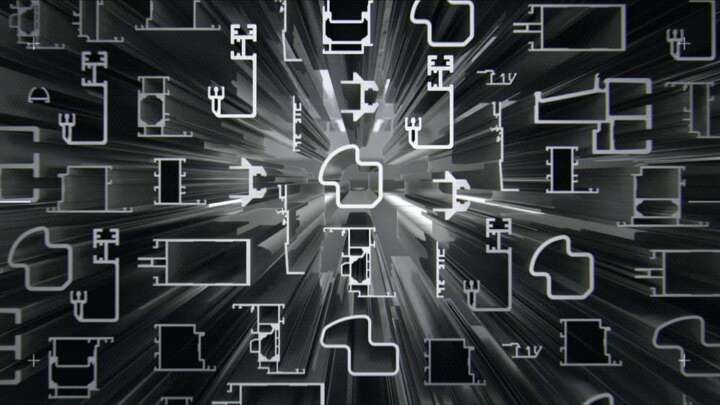

At the Swiss company PBT AG, we develop and produce profile bending machines and digital control systems that satisfy the highest requirements in terms of quality and technical performance capabilities. Through the use of intelligent processes, our technologies have been setting industry standards since 1991, and are used in practically all segments of the metalworking industry: automotive, aerospace, window and façade engineering, conveyor technology, and many more rely on the quality and precision of our profile bending machines.

Operation without expert knowledge

Unparalleled in the sector - our digital controls are suitable for all operators. They allow handling of profile bending machines and precise bending after just a short training period and without any programming skills.

Using a modern multi-touch display, even complex bending programs can be prepared, managed and executed comfortably. Here the graphic display of the programmed workpiece allows visual inspection of the programmed data; notes and information on the process are available to everyone via PDF documentation.

In addition, our uncompromising profile bending machine control system PC400 can be utilized as a central controlling hub for machine periphery (supplementary modules, robots, saws, MMS etc.).

Latest news

New product: PBT15

ProductsThe PBT15 is the latest model in our product line, featuring a compact design and versatile applications. Configurable with D40 or 65mm shaft diameters, it offers maximum flexibility from tight radii to substantial profiles. Its outstanding price-performance ratio combines top-notch performance with cost-effectiveness.

Mehr Informationen unter: https://www.pbt-ag.com/en/prod...

News

New product: PBT15

ProductsThe PBT15 is the latest model in our product line, featuring a compact design and versatile applications. Configurable with D40 or 65mm shaft diameters, it offers maximum flexibility from tight radii to substantial profiles. Its outstanding price-performance ratio combines top-notch performance with cost-effectiveness.

Mehr Informationen unter: https://www.pbt-ag.com/en/prod...

FAQ (Frequently asked questions)

PBT AG is a leading manufacturer of high‑precision profile bending machines and digital bending control systems. Since 1991, the company has been developing and producing bending machines used worldwide in industries such as automotive, aerospace, facade and window construction, conveyor technology, and many other metalworking sectors.

PBT stands for Swiss engineering, exceptional precision, and innovative profile bending technology.

The range of services includes comprehensive investment consulting and project planning, prototyping, the construction of custom tools, assembly and commissioning, as well as training, maintenance, modernization, and retrofit solutions.

PBT AG’s headquarters is in Weinfelden, Switzerland.

Through PBT Germany in Siegen, the company also maintains a strong presence in the German market.

In addition, PBT cooperates with a global network with selected partners who provide sales, service, and technical support.

PBT AG positions itself as a solutions provider, not just a machine builder.

Key differentiators include:

A holistic approach to every bending requirement

Highly flexible modular machine concepts

Precision‑engineered custom tools for complex profiles

Intuitive digital control systems (e.g., PBT‑Control)

Support through all project stages: design → prototyping → series production → training

Over 30 years of experience combined with strong innovation

Tailor‑made solutions for single parts, small batches, and fully automated industrial systems

Yes. PBT AG provides customized automation solutions that cover the entire process—from initial concept and planning to final acceptance. Whether you require partial automation or a fully automated production cell, PBT designs systems that are precisely tailored to your batch sizes, production workflows, and efficiency requirements.

Using modern robotics and handling technology, PBT seamlessly integrates loading and unloading processes as well as complete bending operations. Open interfaces ensure that existing machines, production lines, and external systems can be connected without limitations.

The result: maximum precision, productivity, and long‑term investment security.

Your benefits at a glance

Comprehensive consultation and project evaluation

Fully customized systems engineered to your requirements

Flexible automation solutions for small, medium, or large‑scale production

Complete turnkey delivery – from concept to final acceptance

The PBT product range includes bending machines for every profile size and application:

ARKUS12 – ideal for small profiles and tight radii

PBT15 – the newest model offering maximum flexibility and modularity

PBT25 – versatile and fast to reconfigure for changing production needs

PBT Servo Wide – for demanding bending tasks requiring high force

Helix Servo – for large profiles and complex bending geometries

PBT also provides control systems, bending software, rollers, tools, and specialized accessories.

PBT profile bending machines are used in numerous metalworking industries, including:

Many more specialized applications

With this range, PBT is one of the most versatile solution providers in the profile bending market.